Professional Plastics Thermoforming Video YouTube

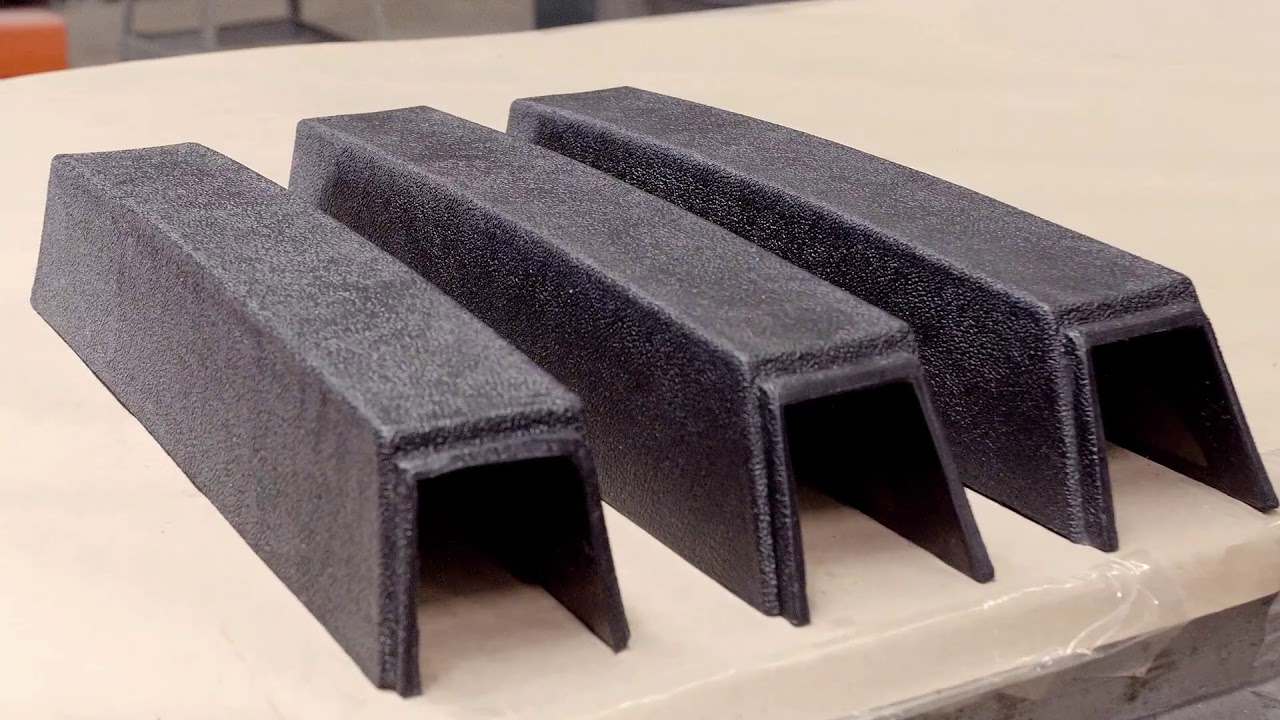

The process of evacuating air from the sealed space between the hot sheet and the mold, thus allowing atmospheric pressure (14.7 p.s.i.) to force the sheet to conform with the contour of the mold. Applications: Non-critical appearance covers, dunnage trays, internal covers. Competes with sheet metal and fiberglass. A low- to medium-volume process.

Thermoforming Plastics and Thermosetting Plastics GCSE Design and Technology AQA Revision

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. A plastic sheet is heated in an oven then stretched into or onto a mold and cooled to a finished form.

INTECH Thermoforming

Some of the most common are: Introduction Vacuum Forming: This is the most basic process. In vacuum forming, vacuum alone is used to mold the part. The forming "pressure" is thereby limited to atmospheric pressure, about 14.7 psi. Pressure Forming: In pressure forming a pressure box is used on the side of the part opposite the mold.

Thermoforming Products Plastics Unlimited

Step 1 is to heat the plastic sheet to a pliable temperature, then shape it to the mold using vacuum pressure, air pressure or a combination of both. Once the material has formed to the mold, it's cooled and removed from the mold, keeping its final shape. Since the final project cools against the mold surface under ambient temperatures.

Solution to problems associated with PET Thermoform plastic Packaging South Asia

Plastic sheeting being prepped for heating oven. The process of thermoforming begins by heating thin sheets of thermoplastic material until it becomes pliable and easy to manipulate. While still hot, the plastic is placed onto a rigid backing platform which is most often referred to as a mold. The material is secured by either vacuum pressure.

Which Plastic Materials Are Used In Thermoforming?

First, a plastic sheet is heated to a temperature at which it becomes pliable. Then, the malleable plastic is cooled so it can harden into the desired shape. Types of thermoforming Pressure forming and vacuum forming are the most common thermoforming techniques.

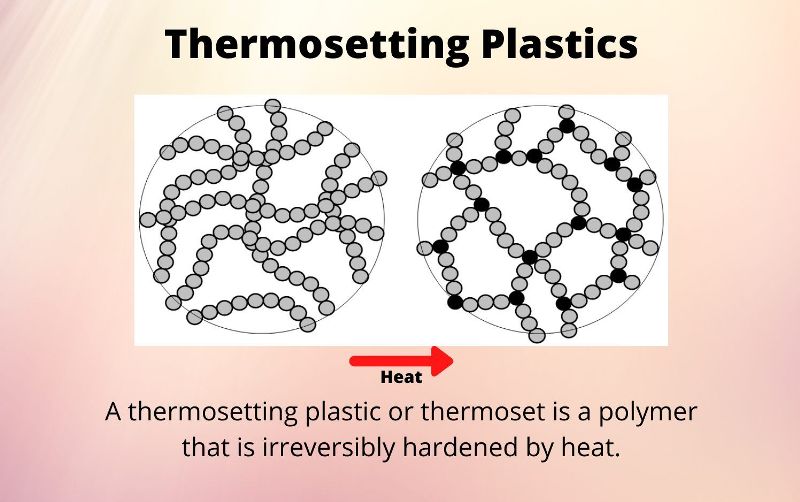

13 Thermosetting Plastic Examples in Daily Life StudiousGuy

Guides 15 minutes read Table of Contents What is Thermoforming? Plastic comes in different sizes, types, colors, and with different material characteristics. The wide variety of plastic makes it a crucial material for manufacturers interested in producing both prototypes and end-use parts for use.

Understanding Thermoforming Plastics Resources Inc.

1) ABS. ABS is a common thermoformed plastic that is made of acrylonitrile, butadiene, and styrene. It can withstand extreme temperatures ranging from -4 to 176 °F. This ensures that the plastic can be molded to any desired shape at high temperatures. ABS is corrosion resistant and impact proof. This makes it an ideal polymer for 3D printing.

Thermoformed Products Lyle Industries

Examples: ABS, HIPS, Polycarbonate Semi-crystalline thermoplastics Difficult to thermoform Examples: HDPE, PP Thermoplastic Triangle HDPE Semicrystalline, difficult to thermoform

Thermoforming · Min Plastics & Supply, Inc.

The process of thermoforming. In the thermoforming process, a thermoplastic sheet is heated to a temperature where it is pliable. It is, then, stretched over a mould and held in place while it cools and solidifies into the desired shape. The thermoplastic sheet is clamped and heated by an oven using either convection or heat until it is melted.

Ways Your Everyday Life Would Be Harder Without Bronze Bushings National Bronze Manufacturing

Noryl® Engineering plastic with outstanding strength, stiffness, and electrical insulating properties. PETG Transparent plastic sheet with good impact resistance and outstanding thermoforming characteristics. Polycarbonate Transparent, strong and stiff thermoplastic with outstanding impact resistance. Polycarbonate Film

Thermoforming Plastics Unlimited

Vacuum forming, a low-cost thermoforming process, offers an economical method of creating large-size, low-volume plastic parts. As a custom thermoforming specialist, Universal Plastics has all the answers to your vacuum forming questions. Read through the most frequently asked questions below, or call us at 800-553-0120 for more information.

What is Thermoforming? Dienamics

A thermoforming primer. First, some basics: The process takes the form of either vacuum or pressure forming. In the former, a heated, pliable plastic sheet is pulled against the contours of the mold by vacuum pressure. "Since pressure is only applied to one side of the sheet," explains Formed Plastics Inc., "vacuum forming is typically.

Cut Sheet Thermoforming Uses Which Type of Clamping System

Plastic Thermoforming is a plastic manufacturing process that applies a force (vacuum or pressure) to stretch a sheet of heated thermoplastic material (thermo) over an engineered mold to create a 3-dimensional shape or part (forming).

Thermoforming · Min Plastics & Supply, Inc.

forming can be ideal when you need durable plastic parts that don't require sharp non-tool side features. Applications: • Non-critical appearance covers, dunnage trays, internal. Thermoforming Design Guide • www.Thermoform.com. Example #2. Assume a part size of 10" x 11" x 5" deep. Surface Area = 2(10" x 5") + 2(11" x 5.

Thermoforming Process Ultimate Guide 2019 With Cost Examples

Procedure A person holds a mold in an open vacuum bed. A sheet of hot plastic will be placed on top and the bed sealed, pulling the plastic down over the mold.